Specifications

| Make | OMEGA |

|---|---|

| Model Range | 920TS / 930TS |

| Type machine | Track Scissor lift |

| Number of slide decks | 2 Hydraulic operated |

| Allowed personal on deck | 5 |

| Drive Type | Track driven |

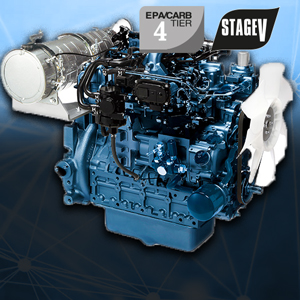

| Engine | KUBOTA V2403CR |

| Max platform height | 11 m |

| Max working height | 13 m |

| Weight | See the document deck config at the documents & download section for detailed info |

| Rotation | 90 degrees |

| Level capabilities | 5° side / side & 5° fore / aft. |

| Lifting capacity - 920TS(kg) | 2.000 kg |

| Lifting capacity - 930TS(kg) | 3.000 kg |