Specifications

| Make | OMEGA |

|---|---|

| Model Range | 1220TS / 1230TS |

| Type machine | Track Scissor lift |

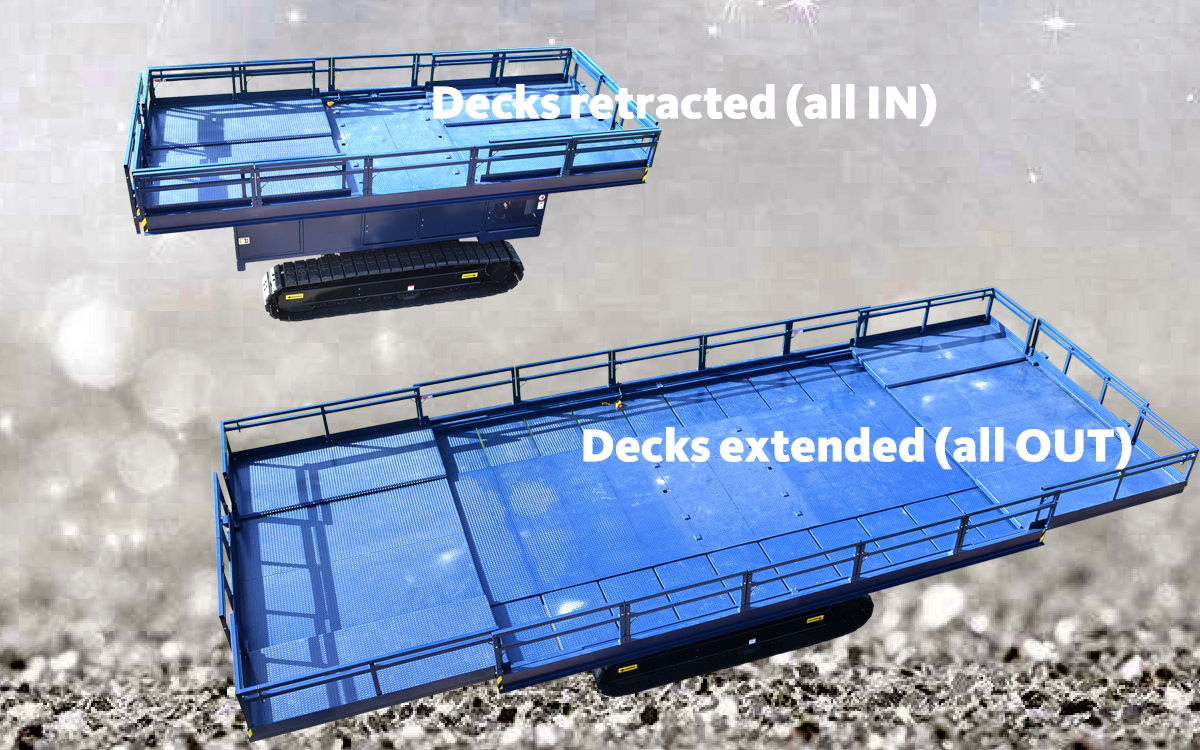

| Number of slide decks | 4 hydraulic operated |

| Allowed personal on deck | 5 |

| Drive Type | Track driven |

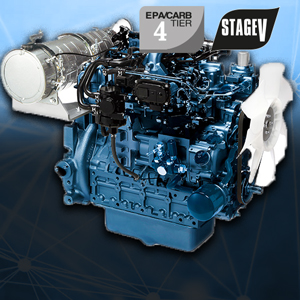

| Engine | KUBOTA V3307CR |

| Max platform height | 8,5 m |

| Max working height | 10,5 m |

| Weight | 18.000 kgup to 21.000 kg |

| Length | 6,9 m |

| Rotation | 90 degrees |

| Level capabilities | 5° side / side & 5° fore / aft. |

| Lifting capacity - 1020TS | 2.000 kg |

| Lifting capacity - 1030TS | 3.000 kg |