Specifications

| Make | OMEGA |

|---|---|

| Model Name | 2085TC |

| Type machine | Track driven knuckle boom Crane |

| Drive Type | Track driven |

| Engine | KUBOTA V2403CR-V2403-CR |

| Weight | 9.500 kg |

| Length | 6,0 mtr |

| Width | 2,3 mtr |

| Crane Turret Rotation | 370 degrees |

| Level capabilities | 10° side / side & 10° fore / aft. |

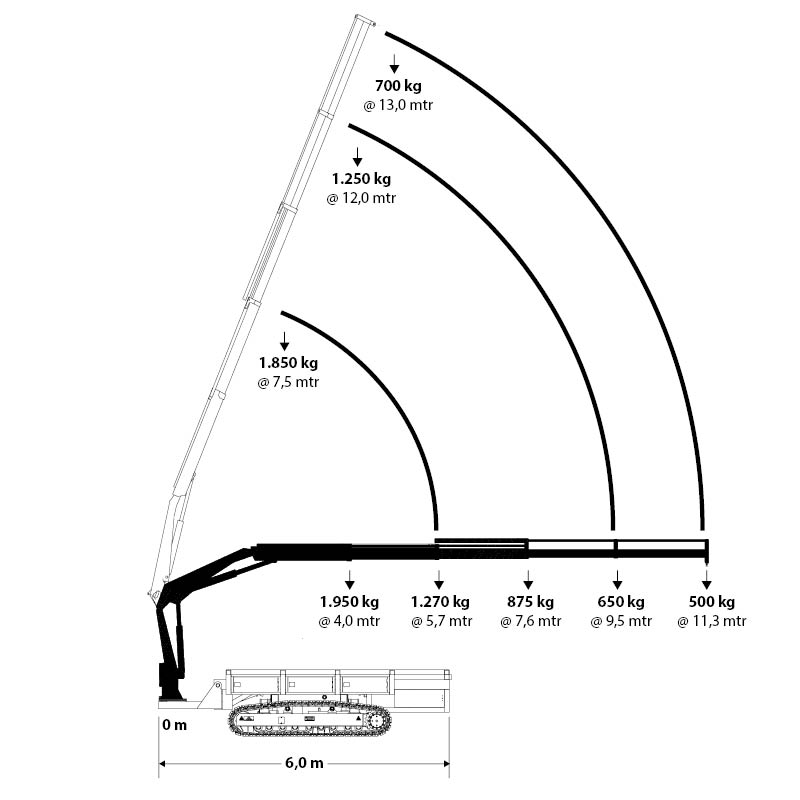

| Lifting capacity - at max outreach | 500 kg |

| Lifting capacity - at min outreach | 1.950 kg |