Specifications

| Make | OMEGA |

|---|---|

| Model Range | 612TS / 615TS |

| Type machine | Track Scissor lift |

| Number of slide decks | 2 |

| Allowed personal on deck | 4 |

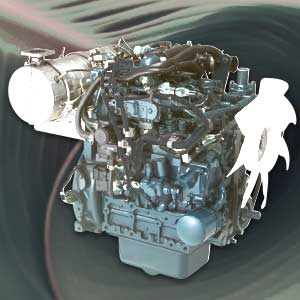

| Engine | KUBOTA D1803CR |

| Min platform height | 2,1 m |

| Max platform height | 8,2 m |

| Max working height | 10,2 m |

| Weight | 8.340 kg |

| Length | 4,16 m |

| Width | 2,2 m |

| Height | 3,2 m |

| Platform width | 2,2 m |

| Platform length - retracted | 4,0 m |

| Platform length - extended | 7,0 m |

| Rotation | 90 degrees |

| Level capabilities | 5° side to side / 5° fore to aft |

| Lifting capacity - 612TS(kg) | 1250 kg |

| Lifting capacity - 615TS(kg) | 1.500 kg |